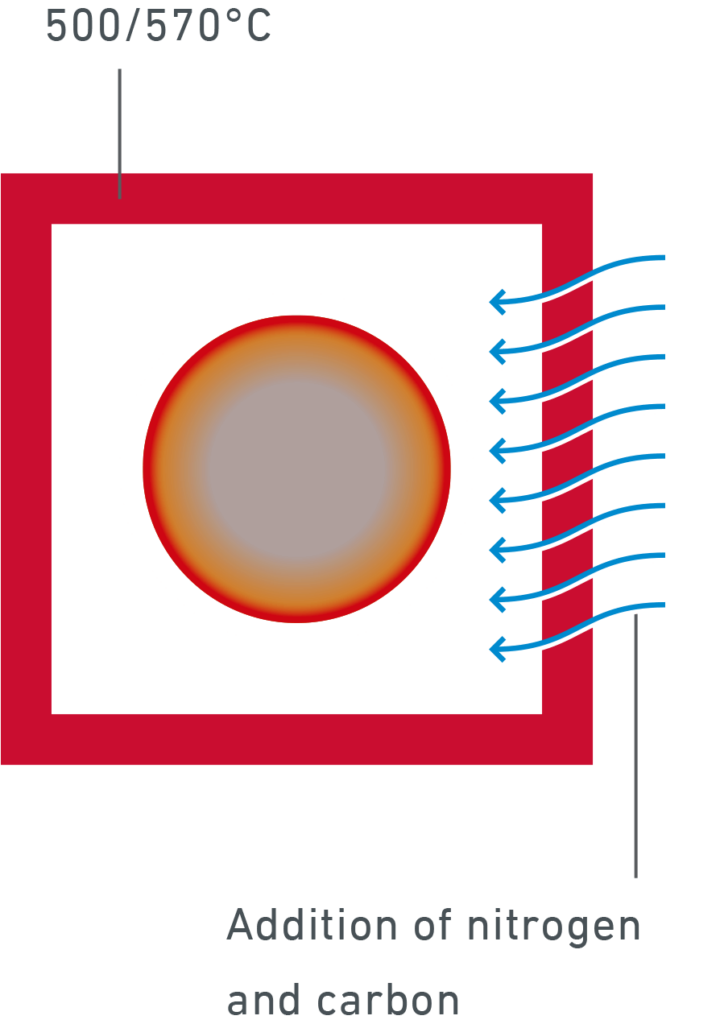

Gas nitriding is a thermochemical surface hardening process without microstructure transformation at low temperatures of approx. 500 to 570 °C. Nitriding ensures hard surfaces and provides high resistance to wear, scratches and abrasion. In gas nitrocarburisation, the process is carried out in an additional carbon-producing atmosphere, whereby two layers ensure high wear resistance and corrosion protection. Our VT-N-OX® process provides additional corrosion protection through subsequent oxidation.

Sustainability factor:

Compared to other hardening processes, the process operates at significantly lower temperatures, with noticeably reduced energy requirements. The absence of quenching in oil also makes nitriding a more environmentally friendly process.