VTN Wilthen

The company was founded in 1958 as a captive hardening plant for the nationally owned combine Fortschritt. The location has belonged to the VTN Group since 1993 and today offers modern, forward-looking technologies. Thanks to a high-performance nitriding department, a new line for low-pressure carburizing (LPC) and numerous other hardening processes, the site is now a universal hardening plant with a wide range of products.

Accordingly, the range of treated parts is wide, from single-part production to large-scale series production.

Technologies and processes:

| System type | Max. dimensions (mm) | Max. total weight (kg) | Max. temperature (°C) | Cooling | Number | ||

|---|---|---|---|---|---|---|---|

| Width | Height | Depth | |||||

| Vacuum furnace | 600 | 600 | 800 | 800 | 1350 | 10 bar abs. N₂ | 1 |

| Multi-purpose chamber furnace | 675 | 610 | 1175 | 600 | 950 | Oil | 2 |

| Chamber tempering furnace | 675 | 610 | 1175 | 600 | 750 | - | 2 |

| Low-pressure carburizing system (LPC) | 760 | 710 | 1210 | 1000 | 1050 | Oil | 3 |

| Chamber tempering furnace | 760 | 710 | 1210 | 1000 | 750 | – |

2 |

| Nitriding furnace | 900 | 900 | 1500 | 2000 | 750 | – | 1 |

| Nitriding furnace | 1200 | 1000 | 1800 | 3500 | 750 | – | 4 |

| Annealing system | various dimensions | 4000 | 950 | – | 2 | ||

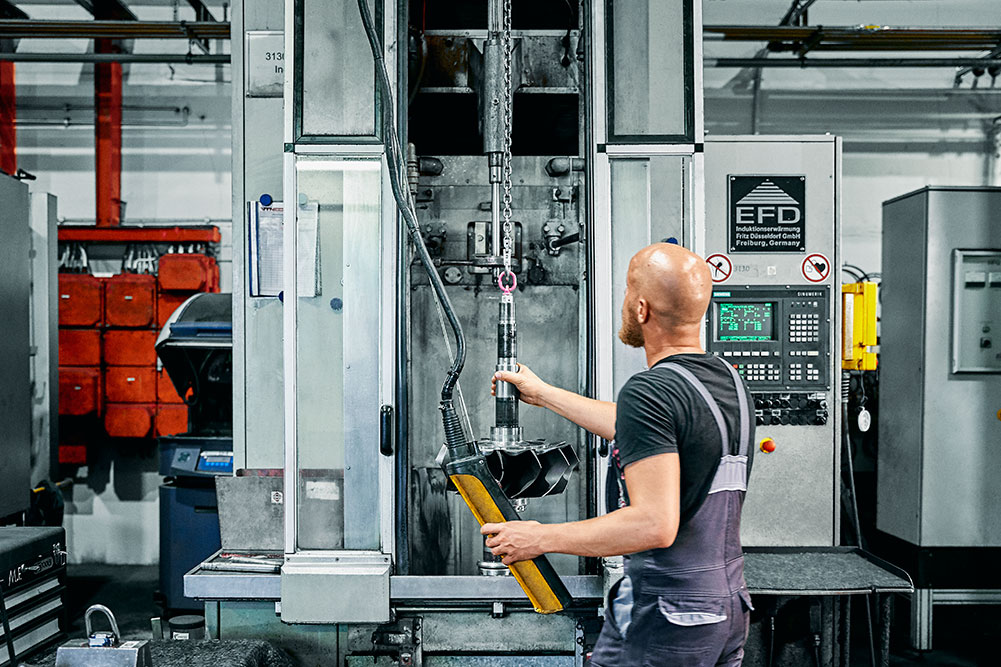

| HF induction system | ø 200 | 2000 | – | 250 | – | – | 2 |

| ZF induction system | ø 180 | 550 | – | 250 | – | – | 2 |

| MF induction system | ø 380 | 2000 | – | 400 | – | – | 1 |

| Blasting system (shot blasting) | On request | – | – | – | 1 | ||

| Blasting plant (glass beads) | On request | – | – | – | 1 | ||

| Straightening press | On request | – | – | – | 1 | ||

| Washing machine (alkaline) | 900 | 1000 | 1200 | 1500 | – | – | 1 |

| Washing machine (vacuum) | 760 | 850 | 1210 | 1000 | – | – | 1 |

| System type | Max. dimensions (mm) | Max. total weight (kg) | Max. temperature (°C) | Cooling | Number | ||

|---|---|---|---|---|---|---|---|

| Width | Height | Depth | |||||

| Vacuum furnace | 600 | 600 | 800 | 800 | 1350 | 10 bar abs. N₂ | 1 |

| Multi-purpose chamber furnace | 675 | 610 | 1175 | 600 | 950 | Oil | 2 |

| Chamber tempering furnace | 675 | 610 | 1175 | 600 | 750 | - | 2 |

| Low-pressure carburizing system (LPC) | 760 | 710 | 1210 | 1000 | 1050 | Oil | 3 |

| Chamber tempering furnace | 760 | 710 | 1210 | 1000 | 750 | – |

2 |

| Nitriding furnace | 900 | 900 | 1500 | 2000 | 750 | – | 1 |

| Nitriding furnace | 1200 | 1000 | 1800 | 3500 | 750 | – | 4 |

| Annealing system | various dimensions | 4000 | 950 | – | 2 | ||

| HF induction system | ø 200 | 2000 | – | 250 | – | – | 2 |

| ZF induction system | ø 180 | 550 | – | 250 | – | – | 2 |

| MF induction system | ø 380 | 2000 | – | 400 | – | – | 1 |

| Blasting system (shot blasting) | On request | – | – | – | 1 | ||

| Blasting plant (glass beads) | On request | – | – | – | 1 | ||

| Straightening press | On request | – | – | – | 1 | ||

| Washing machine (alkaline) | 900 | 1000 | 1200 | 1500 | – | – | 1 |

| Washing machine (vacuum) | 760 | 850 | 1210 | 1000 | – | – | 1 |

Contact

Zittauer Straße 67

D-02681 Wilthen, Germany

Tel.: +49 (0) 35 92/38 55 – 0

Fax: +49 (0) 35 92/38 55 – 33

E-Mail: wilthen@ihi-vtn.com

Felix Pfaff

Tel.: +49 (0) 35 92/38 55 – 21

E-Mail: felix.pfaff@ihi-vtn.com

Marcel Noack

Tel.: +49 (0) 35 92/38 55 – 29

E-Mail: marcel.noack@ihi-vtn.com

Georg Hauser

Tel.: +49 (0) 35 92/38 55 – 14

E-Mail: georg.hauser@ihi-vtn.com

Antje Rudolf

Tel.: +49 (0) 35 92/38 55 – 11

E-Mail: antje.rudolf@ihi-vtn.com

Beate Krüger

Tel.: +49 (0) 35 92/38 55 – 22

E-Mail: beate.krueger@ihi-vtn.com

More Locations

VTN Witten GmbH

Herbede-Plant

Rüsbergstraße 75

D-58456 Witten-Herbede, Germany

Tel.: +49 (0) 23 24/93 42 – 0

Fax: +49 (0) 23 24/93 42 – 11

VTN Witten GmbH

Annen Plant

Stockumer Straße 28 (Hall A7)

D-58453 Witten-Annen, Germany

Tel.: +49 (0) 23 02/95 619 – 0

Fax: +49 (0) 23 02/95 619 – 40

VTN Fritz Düsseldorf GmbH

Am Stadtholz 39

D-33609 Bielefeld, Germany

Tel.: +49 (0) 5 21/92 63 23 80

Fax: +49 (0) 5 21/32 54 10