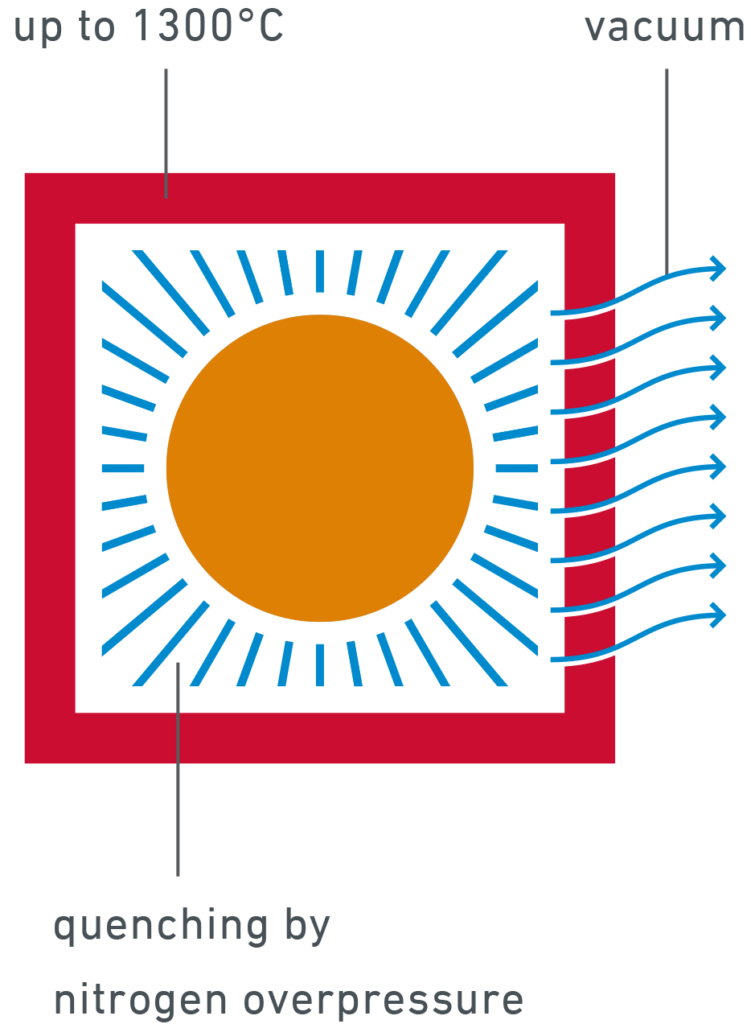

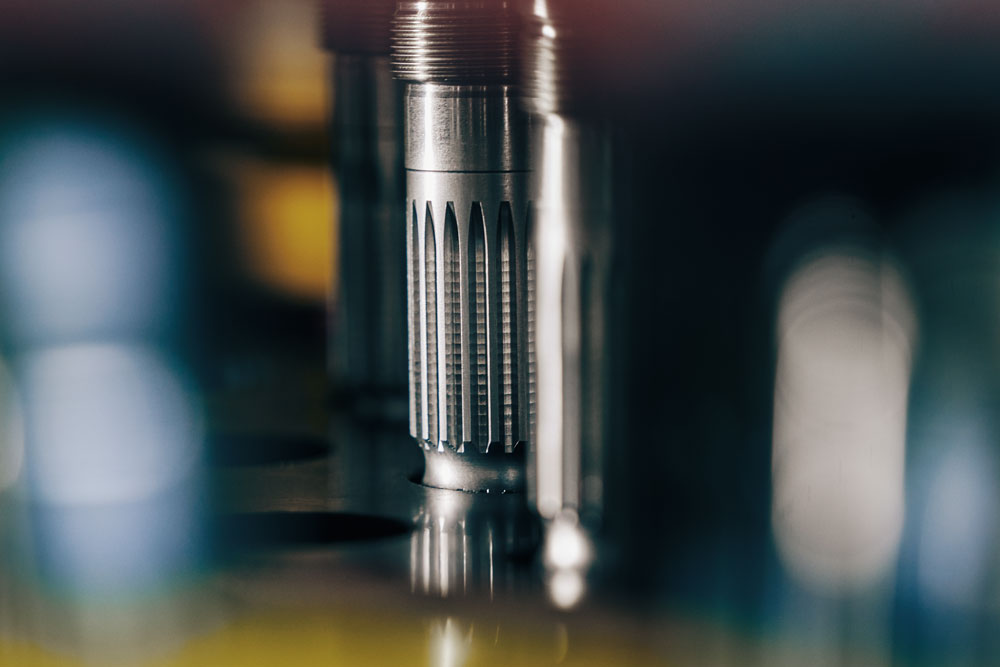

The process offers ideal conditions for highly sensitive components from tool and mould making, plant engineering, medical technology, food technology and aerospace. Components are hardened under controlled vacuum at up to 1,300 °C. Heating takes place under vacuum and subsequent quenching with up to 20 bar nitrogen overpressure. The aim is to produce surfaces free from decarburization and oxidation, eliminating the need for further mechanical processing.

Sustainability factor:

the process is particularly sustainable and environmentally friendly, as it does not generate any direct emissions and can be run on renewable energies.