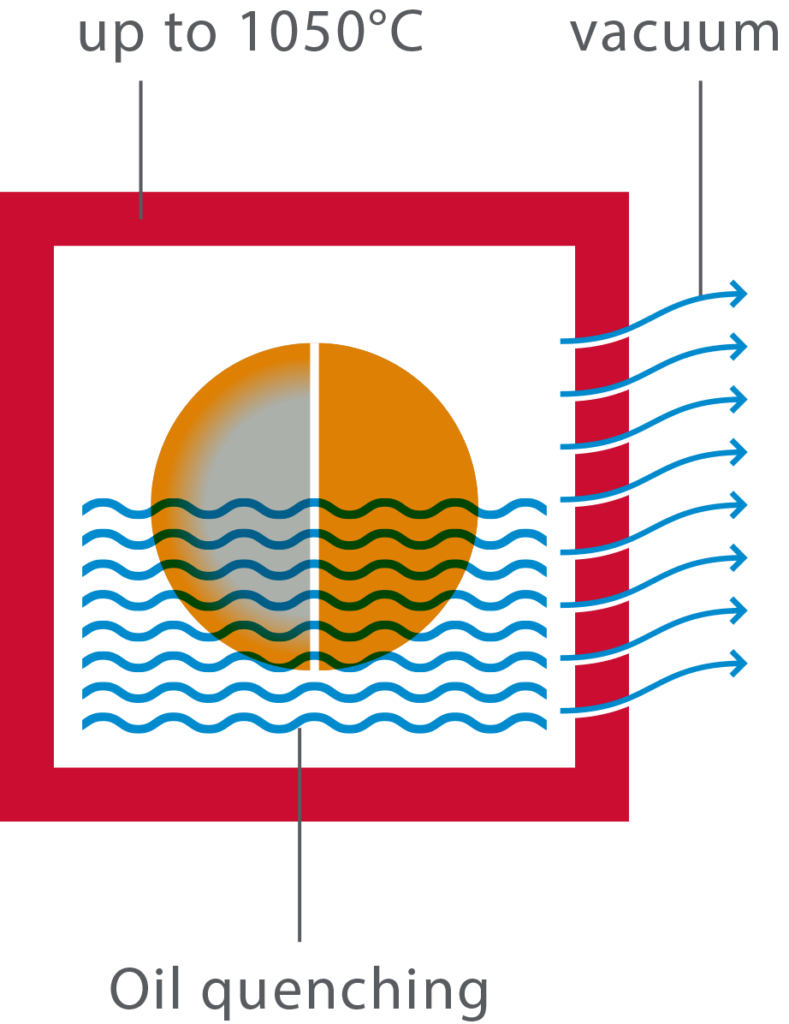

In this process, the application is hardened under vacuum in combination with a fully integrated oil quenching system. The process is suitable for all classic case hardening steels (e.g. 16MnCr5 or 18CrNiMo7-6). The furnaces can achieve carburizing temperatures of up to 1,050 °C. Thanks to oil quenching, this technology can also harden all hardened and tempered steels, ball bearing steels and tool steels without oxidation.

Sustainability factor:

The process meets the most stringent requirements in terms of occupational and environmental protection. The process has no direct emissions and can be operated on renewable energies.