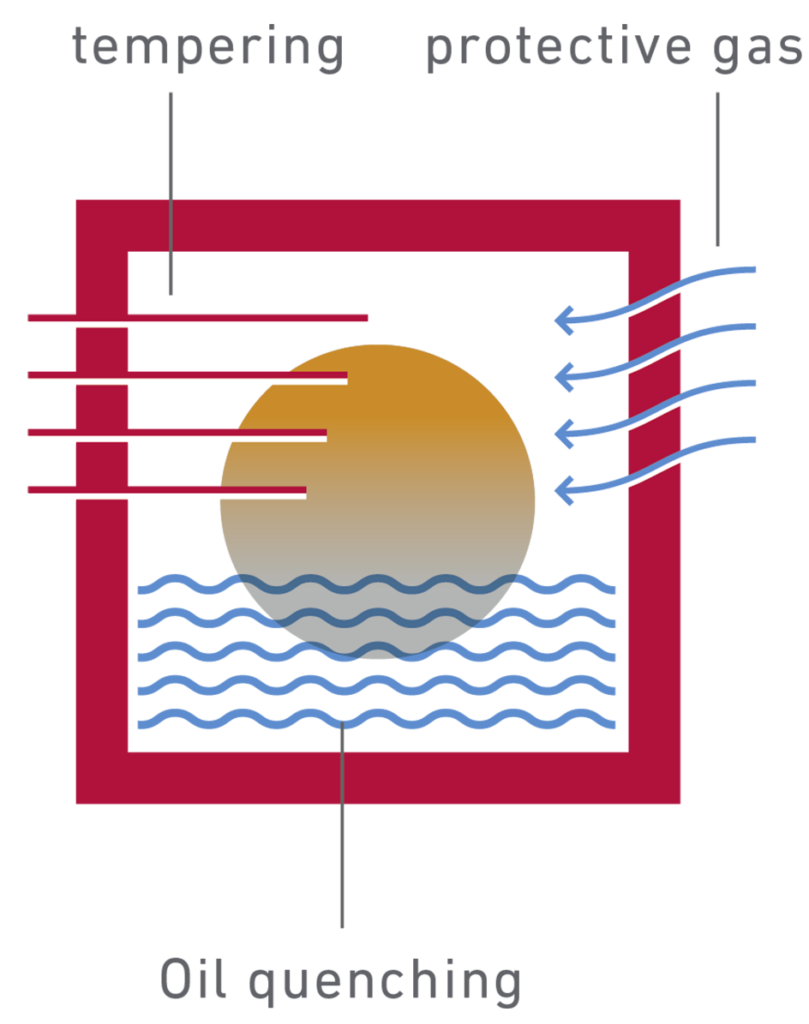

This process refers to hardening with quenching and subsequent tempering. In the first step, the workpieces are heated to the required hardening temperature. Quenching is then carried out in an oil or salt bath, where the maximum hardness of the selected material is reached. The final tempering process at lower temperatures sets the desired hardness or other mechanical properties of the workpiece.

Sustainability factor:

Thanks to state-of-the-art heating and burner technology, we ensure good energy efficiency throughout the entire process.